Next-Battery

Next-Battery’s technology involves unique lithium-ion chemistries with novel nano-structuring technology to effectively “upgrade” a battery electrode’s functional properties. The proprietary process significantly increases the surface area of the metal oxides in the cathode which allows dimension reduction and doping to increase functionalisation and morphology control. This enables cathodes that are ultra-porous, and lithium infused within a nanostructured surface to enable faster lithium-ion transport and electron movement in a more energy dense structure.

Next-Battery’s technology involves unique lithium-ion chemistries with novel nano-structuring technology to effectively “upgrade” a battery electrode’s functional properties. The proprietary process significantly increases the surface area of the metal oxides in the cathode which allows dimension reduction and doping to increase functionalisation and morphology control. This enables cathodes that are ultra-porous, and lithium infused within a nanostructured surface to enable faster lithium-ion transport and electron movement in a more energy dense structure.

Laboratory studies on the cathode by the Next-Battery scientists have shown that the Next-Battery technology can more than double the specific energy of the best commercial lithium-ion batteries today, such as the new Tesla/Panasonic 2170 cell used in the Model 3 battery pack. Recharge time should also improve based upon tests to date.

Next-Battery uses sophisticated and unique production equipment for the manufacturing of the nano-structured cathode that upgrades the performance of the battery. The manufacturing process is scalable and suited for mass production as it could be integrated into existing commercial lithium-ion battery production manufacturing lines allowing for rapid deployment via exclusive licensing arrangements.

Next-Battery’s team consists of several material scientists with decades of experience in the development of semi-conductor materials, thin film deposition of metal oxides, super-capacitor cathodes, conductive and non-conductive films, ceramic and polymer materials for selective ion separation, nucleonic materials, and nano-powders.

The current plan is to have a state-of-the-art prototype battery demonstrated within 5-7 months to show a minimum 50% increase in specific energy along with a faster charge rate. In simple terms, that means the Next-Battery should increase the driving range by up to 50% assuming the same weight of battery.

Within 9-12 months, the plan is to demonstrate a minimum 100% increase in specific energy, which should double the driving range, assuming the same weight of battery. Laboratory updates and results will be ongoing.

Next-Battery has pilot-production equipment and facilities in Ukraine to fast track development activities. The Next-Battery technology team leaders are well known published and respected members of scientific institutes in novel advanced materials’ nano and micro-structures and have developed processes to apply those materials in various semiconductor and functional film applications.

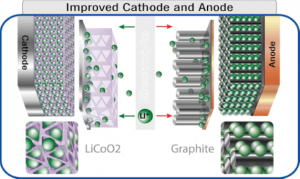

The diagram below of Next-Battery’s improved cathode and anode shows graphically how its unique nano-structure allows more lithium ions (Li+) to be neatly packed into the electrodes, since they have to move back and forth between the cathode and anode during the discharge and charge actions.

The current plan is to have a state-of-the-art prototype battery demonstrated within 5-7 months to show a minimum 50% increase in specific energy along with a faster charge rate. In simple terms, that means the Next-Battery should increase the driving range by up to 50% assuming the same weight of battery.

Within 9-12 months, the plan is to demonstrate a minimum 100% increase in specific energy, which should double the driving range, assuming the same weight of battery. Laboratory updates and results will be ongoing.

Next-Battery has pilot-production equipment and facilities in Ukraine to fast track development activities. The Next-Battery technology team leaders are well known published and respected members of scientific institutes in novel advanced materials’ nano and micro-structures and have developed processes to apply those materials in various semiconductor and functional film applications.